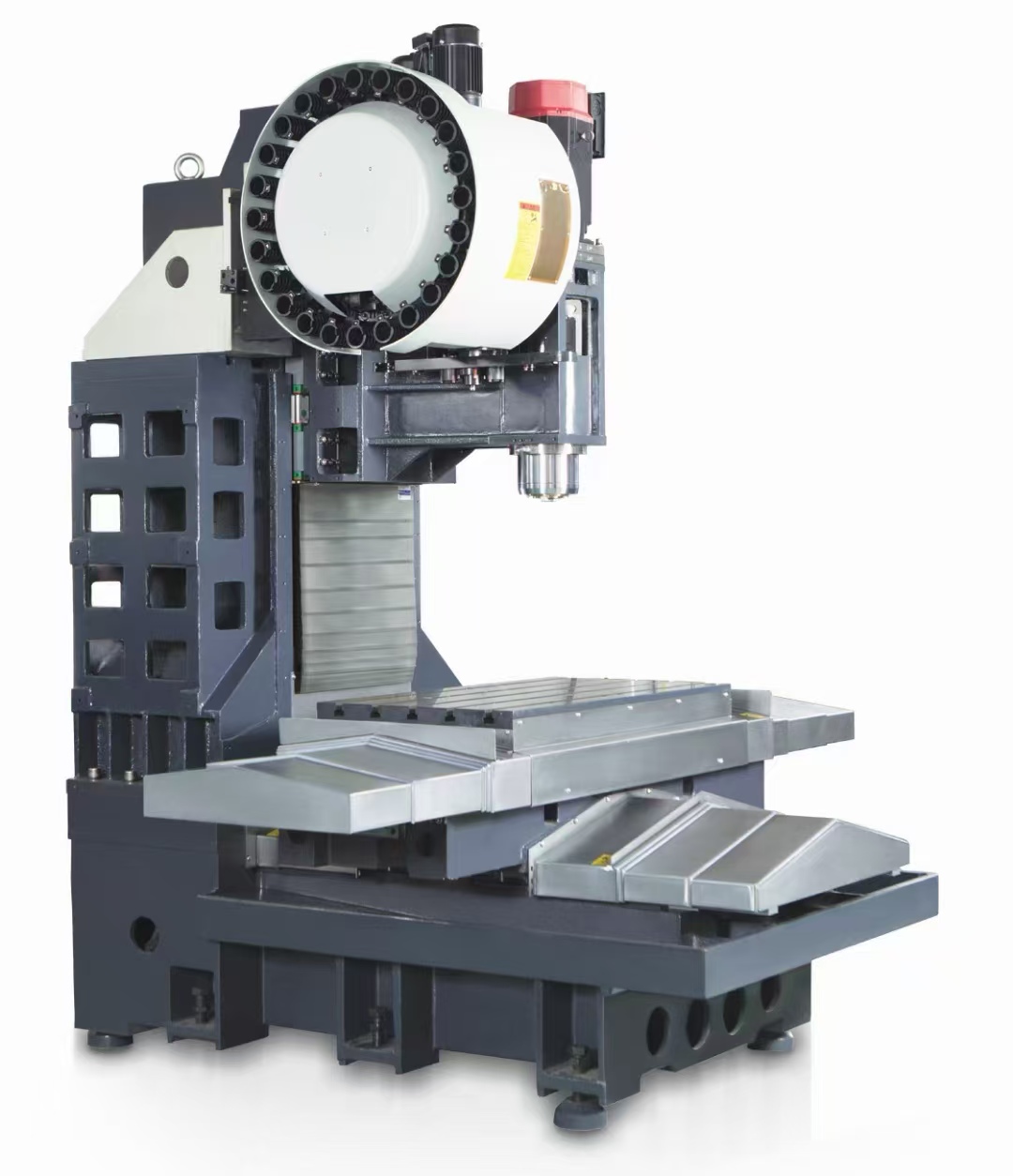

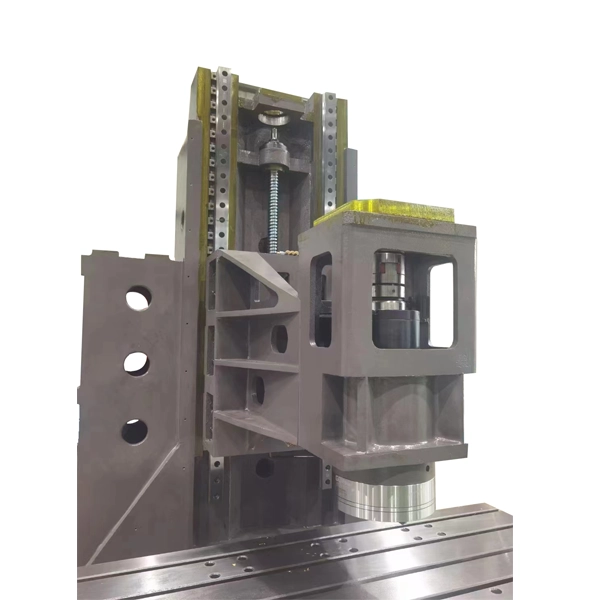

The unique and powerful mechanical structure perfectly embodies high rigidity and lasting stability

Integrated screw base and motor base to ensure high rigidity and stability

Suitable for aerospace, high precision mold, parts, 3C, 5G parts processing tool.

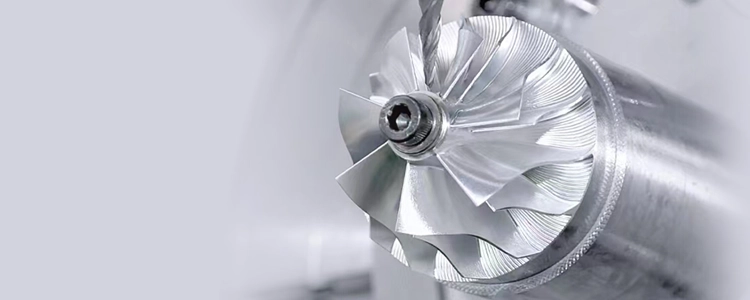

High-end impeller machining/surface, curve, universal machining

| Specifications/Models | Unit | GY-855 | C-855 | GY-1100 | C-165 | GY-1200 | GY-1300 | GY-1500 | |

Processing range |

X-axis travel | mm | 800 | 820 | 1100 | 1100 | 1200 | 1300 | 1500 |

| Y-axis travel | mm | 550 | 550 | 600 | 650 | 700 | 700 | 800 | |

| Z-axis travel | mm | 550 | 600 | 600 | 700 | 600 | 700 | 700 | |

| Distance from spindle nose to work surface | mm | 120-670 | 120-720 | 120-720 | 150--850 | 80-680 | 120-820 | 185-885 | |

| Distance from spindle center to column track plane | mm | 595 | 560 | 650 | 747 | 785 | 750 | 865 | |

| Table specification | Bed dimension | mm | 1000*550 | 1000*500 | 1200*600 | 1250*600 | 1360*700 | 1400*700 | 1600*800 |

| Table T-slot dimensions | mm | 5-18*90 | 5-18*100 | 5-18*100 | 5-18*115 | 5-18*122 | 5-18*110 | 7-22*110 | |

| Maximum bearing capacity of table | kg | 500 | 500 | 800 | 850 | 1000 | 1200 | 1500 | |

| Spindle specifications | Speed of mainshaft | rpm | 8000/10000/12000/15000 | 6000/8000/10000 | |||||

| Spindle specifications | / | BT40/ BBT40/ HSK A63 | BT40/BT50 | BT40/BT50 | |||||

| kind of drive | / | Belt type/ Direct connection | |||||||

| Electrical machinery | Spindle motor power | kw | 11/15 | 11/15 | 11/15 | 15/18 | 15/18 | 15/18 | 15/18 |

| X, Y, Z axis motor power | kw | 3*3*3 | 3*3*3 | 3*3*3 | 3*3*3 | 3*3*3 | 3*3*3 | 4.5*4.5*4.5 | |

| Tool magazine | Capacity | T | 24/30 | ||||||

| Feed | X, Y, Z axis fast feed | m/min | 48/48/48 | 48/48/48 | 36/36/36 | 36/36/36 | 36/36/36 | 24/24/24 | 30/30/30 |

| X, Y, Z axis cutting feed | m/min | 1-10 | 1-12 | 1-10 | 1-12 | 1-10 | 1-10 | 1-10 | |

| Screw, guide rail specifications | X, Y, Z axis screw specifications | mm | 4016/4016/4016 | 4016/4016/4016 | 4012/4012/4012 | 4012/4012/4012 | 4012/4012/4012 | 4512/4512/4512 | 5010/5010/5010 |

| X, Y, Z axis guide specifications | mm | 35/45/45 | 35/45/45 | 45/45/45 | 45/45/45 | 45/55/45 | 45/45/45 | 55/45/55 | |

| Precision | Positional accuracy | mm | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 |

| Repeated positioning accuracy | mm | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | |

| Machine Specification | Machine size(LxW xH)(about) |

mm | 2600*2200*2400 | 2700*2300*2640 | 3100*2300*2600 | 3900*2400*3000 | 3600*3000*2700 | 3400*2700*2800 | 3700*2900*3800 |

| Weight of machinery(about) | kg | 5800 | 6800 | 7800 | 9000 | 10000 | 9800 | 15000 | |

| Because technology is constantly updated, the above parameters is only for your reference | |||||||||