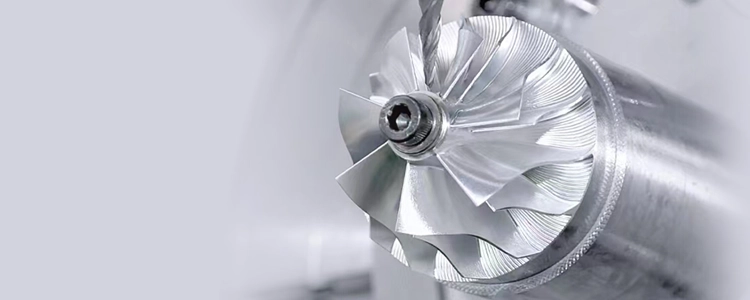

The unique and powerful mechanical structure perfectly embodies high rigidity and lasting stability

Suitable for 3C, 5G, glass, graphite, electrode, ceramic, automobile lamp mold, copper electrode processing, high precision processing

| Specifications Models | Unit | G600 | G800 | G1000 | G1100 | G1200 | G1300 | G1600 | G2000 | G2500 | G3000 | |

| Processing range | X-axis travel | mm | 600 | 600 | 1000 | 1100 | 1200 | 1100 | 1100 | 1300 | 2600 | 3000 |

| Y-axis travel | mm | 500 | 800 | 1000 | 700 | 1000 | 1300 | 1600 | 2000 | 1800 | 2000 | |

| Z-axis travel | mm | 250 | 350 | 500 | 600 | 600 | 600 | 700 | 700 | 700 | 800 | |

| Distance from spindle end face to work surface | mm | 100-350 | 100-450 | 100-600 | 100-700 | 150-750 | 100-700 | 100-800 | 100-800 | 150-850 | 150-950 | |

| Gantry width | mm | 700 | 700 | 1200 | 1200 | 1300 | 1200 | 1200 | 1400 | 1850 | 2020 | |

| Table specification | Table specification | mm | 600*500 | 800*600 | 1000*1000 | 1100*700 | 1200*820 | 1300*1000 | 1600*1200 | 2000*1100 | 2600*1600 | 3200*1700 |

| T-slot dimensions | mm | 5*14 | 5*14 | 7*14 | 7*14 | 7*14 | 7*14 | 7*14 | 7*14 | 10*22 | 10*22*200 | |

| Maximum bearing capacity of table | kg | 300 | 400 | 600 | 800 | 1000 | 1500 | 2000 | 3000 | 4000 | 6000 | |

| Main specification | Speed of mainshaft | rpm | 12000/15000/20000/24000/30000 | |||||||||

| Spindle nose code | / | BT40/BBT40/HSK E40/HSK A63 | ||||||||||

| Kind of drive | / | Direct connection/ Inner Tibetan spindle/ Belt-type | ||||||||||

| Feed | X, Y, Z axis fast feed | m/min | 15/15/15 | 15/15/15 | 15/15/15 | 24/24/24 | 24/24/24 | 24/24/24 | 24/24/24 | 24/24/24 | 2012/12/10 | 2012/12/10 |

| Cutting feed | m/min | 12 | 12 | 12 | 10 | 10 | 10 | 10 | 10 | 7 | 7 | |

| Tool Magazine | Capacity | T | 8/12/16/24/30/40/60 | |||||||||

| Motor | Spindle power | kw | 7.5 | 7.5 | 11 | 15 | 15 | 15 | 18 | 18 | 22 | 22 |

| X, Y, Z axis motors | / | 1/1/1 | 1.5/1.5/1.5 | 1.5/1.5/1.5 | 2/2/3 | 3/3/3 | 3/3/4.4 | 3/3/4.4 | 3/3/4.4 | 40/30/30 | 50/30/30 | |

| Precision | Positional accuracy | mm | ±0.005/300 | |||||||||

| Repeated positioning accuracy | mm | ±0.003/300 | ||||||||||

| Machine Specifications | Machine size | mm | 2700*2100*2400 | 2100*2100*2550 | 3000*2500*2800 | 3500*2800*2800 | 3800*3000*3000 | 3100*2550*2800 | 5600*2850*3000 | 7000*3750*3000 | 7150*4100*4500 | 7200*4500*4500 |

| Machine weight | T | 4 | 5 | 6 | 8 | 10 | 12 | 15 | 20 | 25 | 30 | |

| Because technology is constantly updated, the above parameters is only for your reference | ||||||||||||